Our unidirectional carbon fiber sheet made by T300 or T700 carbon fiber material, using multilayer unidirectional prepreg carbon fiber composite and epoxy resins under high temperature and high pressure. Each sheet we sell is guaranteed to not contain any fiberglass and has a very high carbon-fiber content with low resin weight.

These unidirectional carbon sheets consist of multilayers carbon fiber, and 2 sides have a gloss finish.

The unidirectional carbon fiber sheets are composed of multiple layers of unidirectional carbon fiber prepreg /carbon fiber unidirectional fabric. These unidirectional carbon fiber fabrics are pre-impregnated with high quality epoxy resin, which is formed after the epoxy resin is cured in high temperature and high pressure equipment strong carbon fiber plate. Different from wet layup, our high temperature and high pressure equipment curing process can always produce flat, lightweight sheets with minimal voids and buildups.

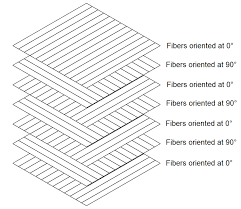

The following is the composition of the unidirectional carbon fiber plate:

Advantages of unidirectional carbon fiber sheets:

Unidirectional carbon fiber fabric has the greatest strength in 2 directions (along the fiber direction) and is very stiff. When processing and producing carbon fiber sheets, unidirectional fabrics can be overlapped in different directions to achieve strength in multiple directions without sacrificing stiffness. Similarly, in the process of layup, the unidirectional fabric can be layered with other carbon fiber fabric weaves to obtain different direction strength characteristics or aesthetics. For example, our conventional 3K twill matte carbon fiber sheet is layered with a layer of 3K fabric on each side surface. Carbon fiber cloth gives the surface the iconic carbon fiber appearance.

The weight of unidirectional carbon fiber cloth is very light, even lighter than their woven counterparts. This allows for better control of precision parts and precision engineering in the layups.

In terms of manufacturing cost, unidirectional carbon fiber cloth is cheaper than woven carbon fiber cloth, because the weaving process is also part of the cost, so using unidirectional cloth as the core material of the carbon fiber plate can save costs and achieve high performance and high strength.

The difference between the unidirectional carbon fiber sheet and 3K weave carbon fiber sheet is just the surface is different, one is the unidirectional cloth surface, and the other is the 3K woven surface; the internal structure is exactly the same.

· Color: Black

· Lots of sizes to choose, our standard size is: 400×500mm, 500×500mm, 500×600mm, 1000×1000mm

· Varying thickness are available starting at 0.2mm to 25mm

· Composition: Unidirectional carbon fiber multilayers with resin adhesive

· Surface Finish: Unidirectional carbon fiber gloss

The application of unidirectional carbon fiber:

Unidirectional carbon fiber can be cut to drone frames, racing car chassis and model boats, model rockets, bicycles and entertainment sticks (hockey, hiking, lacrosse, etc.). Composite parts used in automobiles and other multi-dimensional applications that require comprehensive strength enhancement should use different weaving methods, such as plain weave, twill weave or forged weave. You can also find these carbon fiber materials on our website.

If you want to know our unidirectional carbon fiber sheet price or cut some carbon fiber parts, please tell us here or send email info@jinjiuyi.net