How to cut carbon fiber board?

Carbon fiber composites have excellent properties and are currently used in a wide range of manufacturing. Carbon fiber sheets are the primary products before they are processed into specific parts. For the cutting of carbon fiber board, many manufacturers of processing products do not know much. Because of their high price, blind attempts will bring great economic losses. Shenzhen Jinjiuyi Electronic Technology Co., Ltd. explains how to cut carbon fiber sheet, hope it helpful to you.

What issues should be paid attention to when processing carbon fiber sheets?

The carbon fiber board is composite of polyurethane resin and carbon fiber yarn, and the carbon fiber is resistant to high temperatures but the ordinary resin not resistant to high temperatures. When carbon fiber sheet processing is performed, if high temperature is caused, it will become basically soft, it is difficult to cut carbon fiber directly at this time, and it is extremely damage to the cutting tool. Therefore, it is necessary to reduce the temperature when cutting carbon fiber sheets. Carbon fiber cloth has a special carbon fiber cutting machine. There is no special tool for cutting carbon board, the traditional material cutting method is equally applicable. For example, mechanical cutting, water cutting, ultrasonic cutting, laser cutting, etc. can be used for cutting carbon fiber board.

Introduction to the cutting method of carbon fiber board:

1. Mechanical cutting:

Carbon fiber board generally uses a grinding wheel cutting machine. When the grinding wheel is cutting, it must maintain a very high speed to avoid burrs. For precision machining, it can also be cut by machine tool alloy tools (eg pineapple knife). However, the carbon plate has great damage on the cutting knife, and use the worn tool to cutting, the finished product has many burrs, poor finish and low efficiency.

2. Water cutting:

The method of water cutting is also called water jet, which is formed by pressure injection of water. Water jet cutting is available in both sanded and sand less form. Cutting carbon fiber sheets requires the sand cutting method, add hard abrasive to water. Water jets are suitable for cutting solid carbon fiber sheets and are not too thick. This method is suitable for batch processing and simple operation, but the quality of the water cutting machine is increased, and the Finished products cut out by inferior machines are prone to burrs

3. Laser cutting:

If the laser cutting machine is used to cut the carbon plate, it is necessary to increase the power to ensure the cutting effect, and the ordinary low-power laser cutting machine has a poor cutting effect on the carbon fiber product. Laser-cut carbon fiber sheets have burning marks on the edges and are not recommended.

4. Ultrasonic cutting:

Ultrasonic cutting is the use of ultrasonic energy to produce a fine crushing of the material to be cut to achieve the cutting effect. The carbon fiber board cut by the ultrasonic cutting machine is clean and tidy, and the carbon fiber damage is also relatively little, but the cost of batch processing is high.

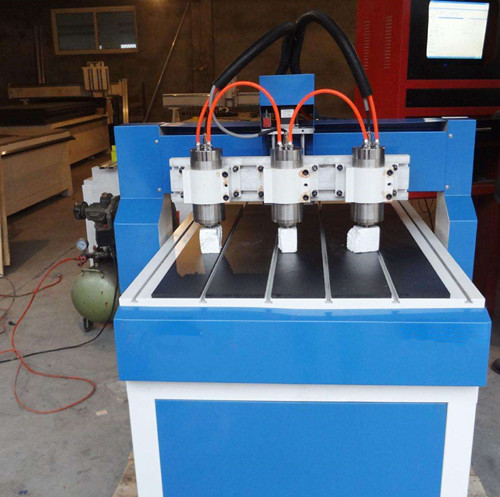

If the carbon fiber board is used for batch cutting, it is recommended to use the grinding wheel cutting or water cutting method. Of course, customers can choose the appropriate cutting method according to the actual needs of quantity, thickness and precision. For the hollow carving processing of carbon fiber sheets, a cnc device such as a numerical control engraving machine is generally used. Shenzhen Jinjiuyi Electronic & Technology Co., Ltd. has complete processing equipment and skilled craftsmanship, and undertakes all kinds of carbon fiber sheet processing business.

Pulished on Oct. 23, 2023

Pulished on Feb. 02, 2023