Carbon fibers have several advantages including high stiffness, high tensile strength, low weight, high chemical resistance, high-temperature tolerance and low thermal expansion. When buying carbon fiber products or parts, we usually pay the most attention to the carbon content. However, what kind of carbon fiber material is used in manufacturing is more important. Because of different material have different applications, Let us give you a detailed difference between the T300, T700 and T800 carbon fiber.

1. Carbon Fiber Composition

Carbon fibers or carbon fibres (alternatively CF, graphite fiber or graphite fibre) are fibers about 5–10 micrometers in diameter and composed mostly of carbon atoms. From the composition, Carbon fiber T300 T700 and T800 are different of carbon content, the mass fraction of T300 is 92.5%, T700 is ˃93%, T800 is ˃96%. Nitrogen is the primary element other than carbon, the former of T300 is 6.96%, T700 is 4.24% respectively, compared with T700 carbon content was significantly higher than that of T300, the carbonization temperature is higher than T300. The content of sodium and potassium in T300, T700S and T800S are < 50ppm.

Carbon fibers are usually combined with other materials to form a composite. When impregnated with a plastic resin and baked it forms carbon-fiber-reinforced polymer (often referred to as carbon fiber) which has a very high strength-to-weight ratio, and is extremely rigid although somewhat brittle.

Different resins used in different carbon fiber material, please check the following data:

RESIN SYSTEM COMPATIBILITY

Type of carbon fiber | Sizing type & amount | Resin system compatibility | Method |

T300 | 40A/B (1.0%) | Epoxy | TY-030B-05 |

40D (0.7%) | Epoxy | TY-030B-05 | |

50A/B (1.0%) | Epoxy, phenolic, polyester, vinyl ester | TY-030B-05 | |

T700S | 50C (1.0 %) | Epoxy, phenolic, polyester, vinyl ester | TY-030B-05 |

60E (0.3 %) | Epoxy | TY-030B-05 | |

F0E (0.7 %) | Vinyl ester, compatible with epoxy | TY-030B-05 | |

T700G | 31E (0.5%) | Epoxy | TY-030B-05 |

41E (0.5%) | Epoxy | TY-030B-05 | |

51C (1.0%) | Epoxy, phenolic, polyester, vinyl ester | TY-030B-05 | |

T800H | 40B (1.0%) | Epoxy | TY-030B-05 |

50B (1.0) | Epoxy, phenolic, polyester, vinyl ester | TY-030B-05 | |

T800S | 10E (0.5%) | Epoxy | TY-030B-05 |

50C (1.0%) | Epoxy, phenolic, polyester, vinyl ester | TY-030B-05 |

From the surface appearance, because of the different spinning process, the surface of T300 and T700 shows different characteristics. The surface of T300 is bark-like and has no obvious grooves, which is the characteristic of wet spinning process, available in 1K, 3K, 6K and 12K tow sizes. And T700 shows a smooth surface, which is the characteristic of dry-wet spinning, Available in 6K, 12K, and 24K tow sizes.

T800 fiber absorbs resin differently which makes it superior in terms of weight reduction, reactivity and outright strength. This never twisted fiber has excellent tensile composite properties and is specifically designed to meet the weight saving demand of aircraft and high performance recreational products. Excellent processability in traditional manufacturing methods (weaving, braiding, filament winding, prepreg, etc). Available in 12K and 24K tow sizes.

2. Carbon Fiber Properties

T300 is the first by the Japanese TORAY company invented in 1970s, it has a fiber modulus of 33-34 Msi or slightly higher, is a type of standard modulus carbon fiber, it is the most cost-effective carbon fibers as measured by tensile strength or modulus per unit cost. So Toray's T300 standard modulus carbon fibers are a recognized industry standard. T700 is a high tensile strength, standard modulus carbon fiber which is another standard industrial fiber. From the performance point of view, carbon fiber T300 and T700 have the same tensile modulus 230GPa and 7μm diameter; but in the tensile strength, the difference is big, T300 3.53GPa and T700 reached 4.90GPa, than the former was increased by 38.8%, and the elongation of T700 increased by 40%, volume density increased by 2.27%.

T800 is an intermediate modulus which tensile modulus of 42 Msi, high tensile strength fiber, with high level and balance composite properties.

Tensile Strength: T300 is 3530 [MPa], T700SC reached 4900 [MPa], while T800SC is 5880 [MPa],

Tensile Modulus: T300 is 230 [GPa], T700S is 230 [GPa], T800 is 294[GPa].

The density: T300 is 1.76 g/ cm2, T700 is 1.80 g/ cm2, T800 is 1.80g/ cm2.

Filament diameter: T300 and T700 are 7 μm, T800 is 5μm, the diameter of T800 is lower than the other two.

Elongation / Strain at Failure: T300 is 1.3%, T700 is 2.1% , T800 is 2%.

CTE (The coefficient of thermal expansion): T300 is -0.41 α⋅10 (-6)/˚C; T700S is -0.3810 (-6) / C, and T800S is -0.4 α ·10 (-6) /°C, T800H is -0.56 α ·10 (-6) /°C.

Specific heat capacity: T300 is 0.777 J/g ·°C; T700S and T700G are 0.752 J/g ·°C, T800H is 0.752 J/g ·°C, T800S is 0.740 J/g ·°C.

Thermal conductivity: T300 is 0.105 J/cm ·s·°C; T700S/T700G 0.096 J/cm ·s·°C, T800H is 0.10 J/cm ·s·°C, T800S is 0.113 J/cm ·s·°C.

Electric Resistivity: T300 is 1.7 x 10-3 Ω·cm; T700S 1.6 x 10-3 Ω·cm, T700G is 1.5 x 10-3 Ω·cm; T800H is 1.4 x 10-3 Ω·cm, T800S is 1.3 x 10-3 Ω·cm.

so you can easily get the data as follow: In short, T800 carbon fiber is 11% stronger than T700 in terms of tensile strength. T700 carbon fiber is 38.8% stronger than T300.

3. Carbon Fiber Costs

T300 carbon fiber as the earliest composite material, it has been widely used for 30 years. In the beginning, the cost was very expensive. The price of T300 material 400 * 500 * 5mm carbon fiber sheet is 130-140 US dollars, but with Toray Corporation T300 shipments are getting larger and larger, and the material cost is getting lower and lower. The T300 carbon fiber cost is now very cheap. The current price of a 400 * 500 * 5mm carbon fiber plate is about $ 80, which is almost half of the price when it was first launched. In terms of cost, the price of T700 is about 40% more expensive than T300, the price of a 400 * 500 * 5mm T700 carbon fiber sheet is about USD $ 120; while T800 is 30%-40% more expensive than T700. This is mainly due to the T700 grade and The raw material cost and production and processing cost of T800 grade carbon fiber are different from T300, resulting in the final price of T700 and T800 is much more expensive than T300.

4. Carbon fiber applications

The internal arrangement structure of the T300 T700 and T800 is different, raw material and produce processing are different, which makes a significant performance difference. So they have a difference in application areas.

At present, the production of carbon fiber products in the civilian market is mainly based on T300, which is a comprehensive consideration of cost performance. In terms of strength, we know that the hardness of steel is very high, but the tensile strength of T300 carbon fiber is 3530MPa, which is 4 times that of steel. It is safer and more reliable to use and has a longer life.

In terms of application areas, steel is generally used as structural parts, while T300 carbon fiber can be used for structural parts, but can also make wallets, clips, business cards, handicrafts and other small items commonly used in daily life, as well as drone frames and Racing car chassis and carbon fiber steering wheels and other products.

Of course, if the product requires higher accuracy and the use environment has certain requirements for product strength, you can choose to use T700 and T800 carbon fiber. T700 carbon fiber is a high tensile strength material that can be used singly as a material to make into products. Because T700 is very flexible, it can greatly reduce the probability of cracking and cracking of the produced carbon fiber products. Therefore, the T700 material is deeply loved by FPV drone enthusiasts. They are used to design drone frames or arms, will not delaminate on impact during flying.

T800 is very light and stiff, but it is also very brittle, so t800 is not suitable to be used to make products separately because while the T800 should be used with T700 carbon fiber together to improve the stiffness of products.

T800 carbon is stronger and lighter and 11% stronger than T700 in terms of tensile strength, It also delivers a swifter return response reaction. T800 is also slightly stronger than T700 in terms of compressive strength too.

T800 used in:

1. High tech field, China has been applied in missile launcher, solid rocket motor shell, satellite and spacecraft.

2. Aircraft and automobile manufacturing, the use of carbon fiber materials in automobile manufacturing can make a breakthrough in the light weight of automobile and bring the social benefit of saving energy. The industry believes that carbon fiber will be used more and more in the future of automobile manufacturing.

3. In railway construction, large top system and sound insulation wall will have good applications in the future, which will also be a promising application area of T800 carbon fiber. The pressure vessel is mainly used on the compressed natural gas (CNG) tank of the car and is also used on the fixed respirator (SCBA) of the firefighters. CNG cans are derived from the United States and European countries, and now Japan and other Asian countries have also shown great interest in the application. Other applications of T800 carbon fiber include machine parts, household electrical appliances, computers and the production of composite materials related to semiconductor devices, which can be used for strengthening, antistatic and electromagnetic wave protection.

5. Carbon fiber lightweight solutions

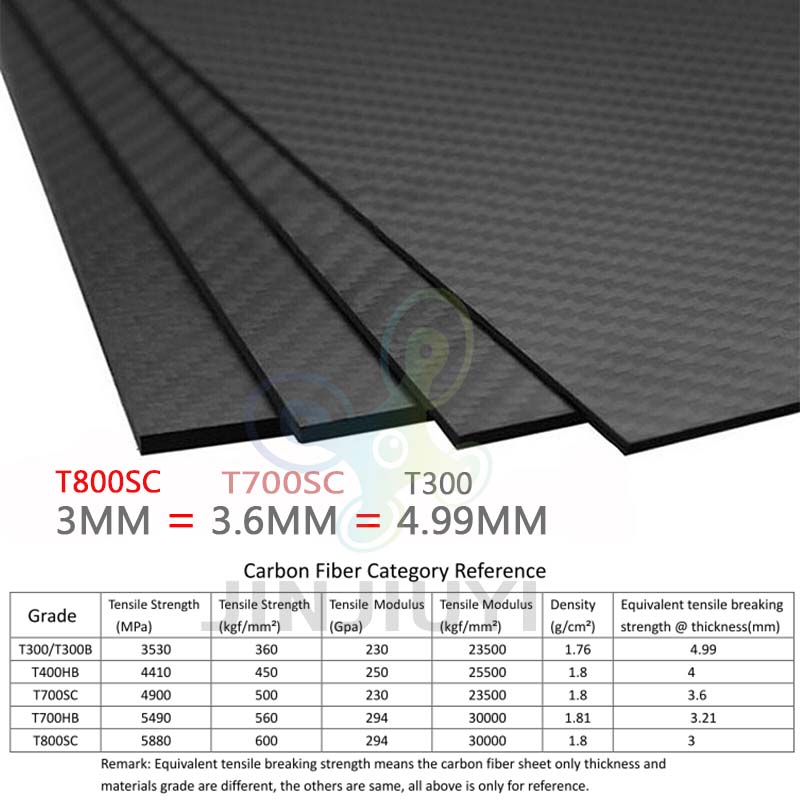

Now more and more products need to optimize the weight of their products to reduce the weight of the products while ensuring the strength of the products. This requires us to update and replace the materials. The following is the lightweight solution we obtained through experiments for reference. Using 4.99mm T300 material is equivalent to the strength of 4mm thickness of T400 material, which is equivalent to the strength of using T700SC 3.6mm thick or T700H 3.21mm thick, or equivalent to the strength of 3mm thickness of T800S. Therefore, many drone design companies use T800 3mm to replace the original 5 mm T300 or use 3.6mm T700 to replace T300 5mm.

In summary, T300 is the most common and cheapest carbon fiber material. T700 is a material that is loved by drone enthusiasts. It has both strength and cost performance which is widely used in the drone industry. T800 carbon fiber is the strongest, and of course the cost is the highest. It is mainly used in high-end manufacturing. It is also necessary to use T800 carbon fiber material to reduce the overall weight of the product.

Pulished on Oct. 23, 2023

Pulished on Feb. 02, 2023