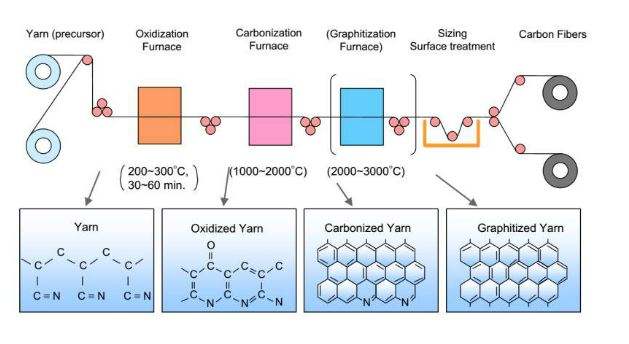

Carbon fiber is a new type of fiber material with high strength and high modulus that contains more than 95% carbon. It is a microcrystalline graphite material obtained by carbonizing and graphitizing organic fibers such as flake graphite microcrystals stacked along the axial direction of the fiber. Carbon fiber is lighter than metal aluminum, but stronger than steel, and has the characteristics of corrosion resistance, high modulus, low density, no creep, good electrical and thermal conductivity, resistance to ultra-high temperature in the non-oxidizing environment, good fatigue resistance, etc. It not only has the inherent intrinsic characteristics of carbon materials, but also has the soft processability of textile fibers, and is widely used in military, aerospace, sporting goods, automotive industry, energy equipment, medical equipment, engineering machinery, transportation, and so on. It is an important strategic material for the development of the national defense industry and national economy.

Carbon fiber classification

1. According to the raw material system:

carbon fiber is mainly divided into viscose, asphalt and polyacrylonitrile (PAN) based three categories, of which PAN-based carbon fiber is the most promising precursor for the production of high-performance carbon fiber because of its simple production process, low cost, high carbonization absorption rate, excellent mechanical properties, etc. The use of its preparation of the best comprehensive performance of carbon fiber, mature and simple production process, the most widely used, production It is the mainstream of the global carbon fiber market and accounts for more than 90% of the total global carbon fiber production.

2. According to the performance:

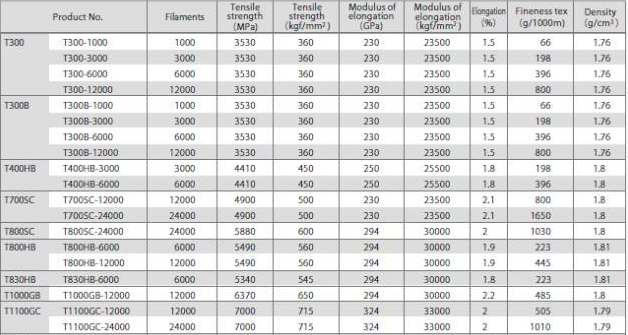

carbon fiber can be divided into general-purpose, high-strength (GQ), high-strength medium model (QZ), high model (GM) and high-strength high model (QM) carbon fiber. Generally divided into high-strength "T" series and high-mode "M" series (specific product models are as follows), the larger the number corresponds to the higher performance level, the tail number with a letter performance level higher than those without letters (such as T300B performance than T300).

3. According to the size of the bundle:

Carbon fiber can be divided into small bundles and large bundles, small bundles of carbon fiber at the beginning to 1K, 3K, 6K mainly, and gradually developed into 12K and 24K, mainly used in the defense industry and other high-tech fields, as well as sports and leisure goods, such as aircraft, missiles, rockets, satellites and fishing gear, golf clubs, tennis rackets, etc. Usually, carbon fiber above 48K is called large filament carbon fiber, including 48K, 60K, 80K, etc.

The performance advantages of carbon fiber

Carbon fiber plate is the most appearing way among the many applications of carbon fiber. Because of its excellent physical and chemical properties, it has replaced some of the aluminum, plastic, steel and other materials in the flat panel, what are the performance advantages of carbon fiber panels?

Light weight and high strength are the well-known advantages of carbon fiber. The density of carbon fiber composite material is very small, about 1.7g/cm3, which is 3/4 lighter than steel structure in the same volume, while the tensile strength, bending strength, shear strength and stiffness of carbon fiber composite material are much higher than most of the structural materials.

The carbon fiber composite material also has unique performance advantages: good X-ray transmission performance, suitable for medical testing equipment. For example, Jinjiuyi carbon fiber team has customized a batch of carbon fiber CT panels for a medical device company, and its X-ray transmission rate is as high as 98%, which can largely reduce the dose of radiation and the damage it brings.

The carbon fiber material is chemically stable and will not deteriorate and rust, it is acid and alkali resistant, anti-oxidation, and has a long service life. Carbon fiber is a material made in an ultra-high temperature environment, and in the actual application process, carbon fiber will be fused with resin to form a carbon fiber composite material, and the general working temperature is 150℃, and its coefficient of thermal expansion is small, basically will not be deformed with the change of working temperature, and the size is stable.

To achieve the purpose of high-temperature resistance, carbon fiber board and other high-temperature-resistant carbon fiber finished products can use phenolic modified epoxy resin base. If you want to ensure that the performance of carbon fiber does not decline while also being able to withstand higher working temperatures, you must choose a matrix material that can withstand higher temperatures, such as PEEK, PPS, PI special engineering plastics or ceramics, metals and other substrates combined with carbon fiber. At present, for high-temperature resistant carbon fiber composites, the choice of coatings may be a good development direction.

Pulished on Oct. 23, 2023

Pulished on Feb. 02, 2023