Carbon fiber is a new high-performance fiber material mainly composed of more than 90% carbon elements. It has excellent properties that are irreplaceable by other materials such as high temperature resistance, abrasion resistance, corrosion resistance, electrical and thermal conductivity, small specific gravity, light weight, high strength and softness. So How to tell the difference between high-quality T300 carbon fiber and low-quality carbon fiber?

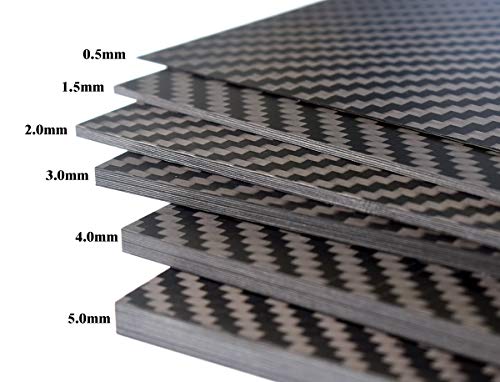

As with any market, some carbon fiber suppliers are more interested in making money than selling you a quality product. When choosing carbon fiber parts, it's important to know whether you're buying a premium carbon fiber product or one with a thin layer of carbon fiber bonded to fiberglass. Genuine carbon fiber parts will contain carbon fiber in every laminate layer and use only high-quality core material. Cheaper products may be made with just a thin layer of carbon fiber on a fiberglass core. This can be achieved with a simple wet layup technique. Being able to spot the difference is important.

Carbon Fiber Back and Fiberglass Back with Carbon Fiber Overlay

An easy way to tell a solid carbon fiber part from a carbon fiber/glass fiber part is to look at the back or inside of the part. The real carbon fiber parts still look like carbon fiber from the back. In other words, you will be able to see the actual fibers of the carbon. Depending on the carbon fiber finish you choose, it may be matte or glossy, but the gloss will be fairly even.

In contrast, a fiberglass part looks like a piece of fiberglass cloth. When you move it around in the light, there are usually some areas that shine more than others. This suggests that the part was formed using a "wet" process, in which a layer of carbon fiber, followed by several layers of fiberglass, is loaded into a mold, which is then poured, brushed with resin, and allowed to cure. Also, a single layer of carbon on fiberglass sometimes allows light to pass through.

Weight of Carbon Fiber vs. Fiberglass with Carbon Fiber overlay

Fiberglass parts with carbon fiber skins are 70% heavier than real carbon fiber parts. This amount can vary depending on the details of the core material used and other factors, but fiberglass is always much heavier.

There are several reasons:

Glass fiber is heavier than carbon fiber.

The wet layup process adds extra weight because excess epoxy is not drawn out of the material by vacuum, as vacuum bagging or epoxy infusion is typically used for higher quality T300 carbon fiber parts.

Extra weight doesn't equal strength. The modulus of elasticity of carbon fiber is four times that of glass fiber.

Glass fiber E=30 GPa (gigapascal)

Carbon fiber E=125 GPa

Carbon Fiber and Fiberglass Edge with Carbon Fiber overlay

When the outer skin of carbon fiber is bonded to the inner layer of fiberglass, a white line will show at the edge due to the white color of the fiberglass. This line is usually masked by drawing a black trim line around the edge. Solid carbon fiber parts will have smooth edges and a uniform black.

Bottom Line

Sometimes cost is a driver, and fiberglass with carbon fiber overlays will definitely be cheaper than solid carbon fiber parts. Knowing what you're buying and understanding its consequences can save you a lot of trouble later in your project. Solid carbon fiber parts will be lighter, stronger and stiffer than fiberglass parts with carbon fiber overlays. If these properties are important to the integrity of the project, then you will want to make sure you are getting real carbon fiber.

Whenever you buy a part, you want to make sure you know what you're getting. Everyone hates to think they got the real deal and find out they got what they paid for. When investing in carbon fiber components, it's critical to know exactly what to look for and make sure you get what you want. Using these techniques to inspect your parts will ensure that you are buying a quality product that will work as specified for years to come.

Pulished on Oct. 23, 2023

Pulished on Feb. 02, 2023