Carbon fibre composes of fibre atoms bonded together with one after the other, in the form of chains. It is due to the strength of these bonds that carbon fibre is quite strong. Along with being strong, carbon fibres are really lightweight. Almost five times lighter than steel, but still five times stronger. Which gives carbon fibres an upper hand.

As it is the most lightweight, yet strong material available in the market today, it is used for a variety of applications, in many different forms. This fibre comes in many different building blocks, such as weaves, yarn, unidirectional, braids, and others, which are used to create composites.

The carbon fiber is made up of really thin fibres, which are twisted together to form a yarn. This yarn is, again, woven into a fabric, called the fibre fabric. This fabric is available in a variety of weaves. The lighter carbon sheets have between 3000 to 6000 thin fibres in a yarn. The heavier carbon sheets, however, can have up to 12,000 thin fibers per yarn. Although polyester flakes are also made of carbon, they are made of carbon and plastic polymers. Polycarbonate sheets are mainly used for commercial premises with translucent materials.

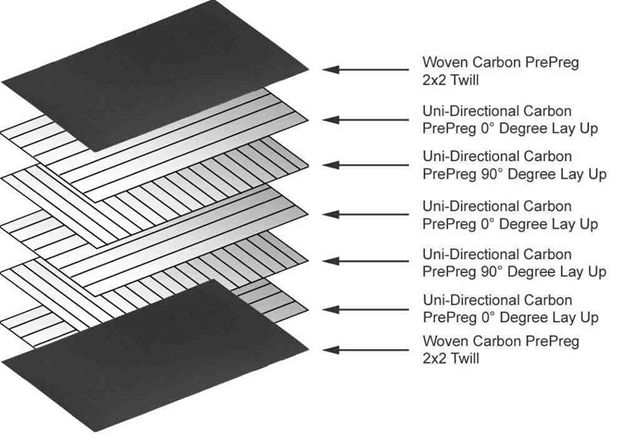

Different kinds of fiber sheets have different strengths properties. The most common kinds of carbon fabric sheets are, harness satin weave, plain weave, unidirectional and twill weave. Before you buy a weave, there are two things you need to keep in mind about them. They are their functionality and appearance.

Every weave has a different look, and people tend to choose the weave with an appearance that suits the nature of their task. Also, the strength of the product also depends upon the kind of weave chosen. If you consider a unidirectional weave, it will be very strong in the direction of the fibers, but weak otherwise. But if you are looking for uniform strength, then plain weaves will be better. So, the point is that the carbon sheets you use depend upon their look and functionality.

How to make a carbon fiber sheet

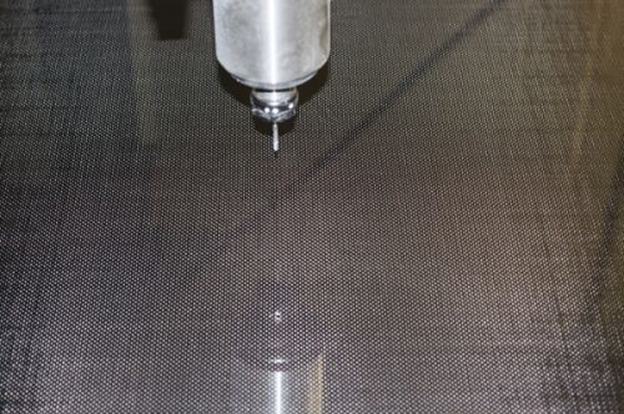

To make a carbon fiber sheet or carbon fibre board, the fabric of the carbon fibre is incorporated with epoxy resins before being heated at high temperatures. Then, several pieces of fabric are layered over a mould to make pieces of various sizes. These pieces are, again, saturated with raisin. Last, but not the least, they are heated so that the resin infuses throughout all the layers.

A carbon fibre sheet is going to stand out due to many reasons.

And they are:

· Lightweight: Carbon fibre is low in density, therefore extremely light. Due to its high strength to weight ratio, the carbon sheet is considered better than steel.

· Low thermal expansion: One issue with the industrial materials is that they tend to expand or contract in temperature changes, which disturbs the overall performance of the industry. The carbon fibre sheet does not do that. It expands and contracts a lot less than other materials.

· High tensile strength: When it comes to tensile strength, carbon sheet is one of the strongest amongst all other commercial fibres and sheets. Carbon sheets are difficult to bend or stretch.

· Durability: Carbon fibre sheets do not wear out as easily as any other material. That is because they have exceptional fatigue properties.

· Resistive towards corrosion: If the carbon fibre sheet is made with appropriate resin, it will be one of the most corrosion-resistant materials in the market.

· Radiolucence: Carbon fibre sheets are invisible in x rays and transparent to radiation. That’s why they have numerous medical applications.

· Electrical conductivity: They are good conductors of electricity, and this property increases their range of applications.

· Ultraviolet resistant: If proper resins are used, they will be UV resistant too.

· If a carbon fibre sheet is pushed, and compressed beyond the capabilities of its strength, then it will shatter or break. It will also break on high impact. A carbon sheet will crack if you hit me with a hammer. When used in machines, holes can be created in the carbon fibre which will increase the chances of breakage.

· As carbon fibre is high-quality material, the cost of carbon sheets is still very high. Even though the prices have decreased in the past few years, the demand has not risen enough to cause a substantial increase in the supply. Therefore, prices are likely to stay the same.

Carbon sheets can be used in many different applications? Here are some of them.

· Carbon fibre sheets will be preferred over sheets of any other material in making robot parts. Carbon sheet enables the robot to be lightweight and make fast movements. Also, it is cheaper and cost-effective.

· Due to their lightweight, they are also used to make parts of machines. Carbon sheets don’t add up to the weight of the machine, so it requires less energy to run.

· Drone frames are being built by using carbon sheets. Using carbon sheets helps drones in many ways. Carbon sheets are easy to process and mould, considering the simplicity of their shapes.

· Carbon sheets are used in making handles of knives due to their visual appeal.

· Also, because of their pleasing appearance, carbon sheets are used to make jewellery and other decorative items.

· They are gaining popularity in the aeroplane industry as well, due to their weight and strength.

· Carbon sheets are also used in the making of boats and other such vessels due to their protective properties.

There are different types of carbon fibers, which fall in mainly two categories

These kind of fibres are the most cost-effective ones if you consider their strength or modulus per unit. Its subcategories are t300 carbon fiber, t400H carbon fibre, t700 carbon fiber, t700S carbon fibre, and t700G carbon fibre. The numbers of thin fibres in these yarns are from 1k to 24k, which 3K is the most widely used and most economical.

These are used for many industrial and recreational purposes. These fibers have 6k, 12k, 18k and 24k thin fibres in them. Their subcategories are t800H, t800S, t1000G, t1100G, t1100S.

Previous:

What is Kevlar Plate?

Previous:

What is Kevlar Plate?

Pulished on Jun. 14, 2025

Pulished on Oct. 23, 2023