What Is The Differences Between Carbon Fiber T700 and T1000?

As we know, T1000 Carbon Fiber is the newest and highest end material, but the most versatile T700 Carbon Fiber to be the highest quality material for FPV racing drones? In this post we will explain the details of the difference between T700 and T1000 Carbon Fiber materials.

What Is Carbon Fiber?

Light and durable advanced material "carbon fiber". It is used for various purposes, from familiar products such as sports equipment to the aerospace field such as rockets and artificial satellites. Carbon fiber is a material made by baking synthetic fiber, which is a raw material of carbon-containing resin, at a high temperature, and refers to those with a carbon atom content of 90% or more. There are two types: "PAN-based" made from a resin called polyacrylonitrile (PAN) and "pitch-based" made from by-products of petroleum refining and coal decomposition.

Carbon fiber is light and durable because carbon molecules are strongly bound by a unique crystal structure by high temperature treatment. It weighs about a quarter of iron, is about 10 times stronger, and is about 7 times harder. It is resistant to rust, has excellent heat resistance, and is easy to transmit electricity.

Carbon fiber is generally used as a carbon fiber composite material mixed with a resin such as plastic, not as a single substance.Originally, Carbon fiber has been adopted from sports and leisure equipment such as golf shafts, tennis rackets, and fishing rods, but nowadays it has many excellent characteristics as a material, so it is now used in aerospace, automobiles / motorcycles, industrial equipment, and medical care. It is used in a wide range of fields such as nursing care / welfare, construction / civil engineering / interior, and attractions. Recently, it is being actively adopted in advanced technology fields such as the realization of large and small UAVs (unmanned aerial vehicles, drones) and air mobility (flying cars, hoverbikes) that require weight reduction.

What Does T700 and T1000 Carbon Fiber Mean?

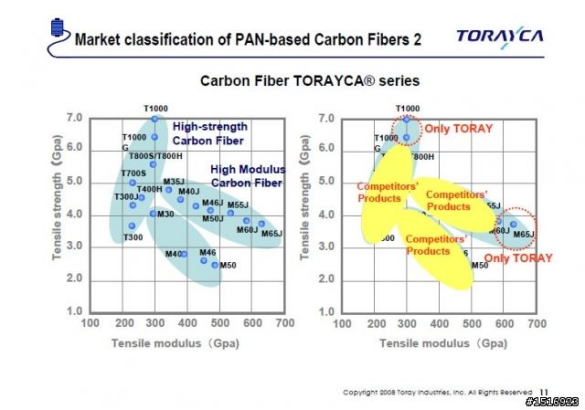

T700 and T1000 refer to the grade of carbon fiber, which is usually measured by tensile strength index. In fact, "T stand" is the standard set by Toray Corporation of Japan for its carbon fiber series products. Toray's T series is widely used to define carbon material grades due to the company's global monopoly on carbon fiber development and production. The letters T signify for the carbon fiber tow's tensile strength, and the numbers 800 and 1000 behind it stand for the rating of tensile strength and tensile modulus.

Carbon fiber is divided into grades from 24 to 60 tons depending on the elasticity modulus (this T represents tons of weight). The larger this number is, the harder the material is used. If you choose a frame that claims high elasticity, it will often be a hard frame. On the other hand, Toray's T series is a high-strength material. There are grades such as T700, T800, T1000, etc., but the elastic modulus of this T series itself is about 24 to 30 tons. Although it has a medium elastic modulus, its high strength makes it a good idea. Elasticity and strength are contradictory elements, and are called high elasticity (high modulus) and ultra-high elasticity (ultra-high modulus). On the contrary, when the elastic modulus increases, the strength decreases and it becomes easy to break. This means that rigid materials are fragile and durable materials are soft.

lTensile strength indicates the ability of a material to resist permanent deformation and damage under the action of external forces.

lTensile Modulus (elastic modulus) refers to the elasticity of a material when stretched. Its value is the ratio of the force required to stretch the material per unit length in the direction of the central axis to its cross-sectional area.

Basically, the higher the number, the higher the performance and the higher the price. Elastic modulus and tensile strength are important for understanding the difference between carbon fibers.

What is The Difference Between Carbon Fiber T700 and T1000?

At present, high-performance carbon fiber products have gradually developed from T700 to T800 and even T1000 and T1100, with a maximum tensile strength of 7.02Gpa and a modulus of 296GPa; they are used in aerospace, automobile manufacturing, rail transit, high-end medical and other fields. However, due to the difference in performance, their application fields are still very different.

1. Performance Difference Between T700 And T1000 Carbon Fiber

The fundamental difference between T700 and T1000 is shown in the performance parameters of carbon fiber itself, such as strength, modulus and other concepts, which have nothing to do with weight, and the size of weight is in the k number, as well as the carbon fiber cloth single square fiber and resin content decided.

T700 Carbon Fiber Specifications

The 0°tensile strength of T700 unidirectional sheet is 1830.7MPa, and the 0°tensile modulus is 99.2GPa.

Pulling strength: 4.9Gpa

Lifting modulus: 240Gpa (T700) / 230Gpa (T700S)

Elongation: 2.0% (T700) / 2.1% (T700S)

Density: 1.80g/cm3

Diameter: 7μm

Tow: 12K24K (T700G) / 6K12K24K (T700S)

Sizing agent: 31E0.5% (T700G) / 50C1.0% (T700S)

Twist shape: no twist

Thermal expansion coefficient: -0.3810(-6)/℃

Specific heat capacity: 0.18Cal/°C

Thermal conductivity: 0.0224Cal/㎝ s ℃

Resistance: 1.6×10(-3)Ω·cm

Carbon content: 93%

Sodium and potassium content: <50ppm

T1000 Carbon Fiber Specifications

T1000 has a tensile strength of 7GPa, a tensile modulus of elasticity of 294GPa, and an ultimate elongation at break of 2.4%. Its high tensile strength is well reflected in its composite material. When it is combined with a suitable resin system, the The tensile strength of the composite material reaches 3.5~3.8GPa. The elongation at break reaches 2.0%.

Tensile strength: 6370 MPa

Pull-up modulus: 294 GPa

Elongation: 2.2%

Density: 1.80g/cm3

Diameter: 5um

Tow: 12K

Sizing agent: 40D 0.7%

Twist: untwisted

Thermal expansion coefficient: -0.55 10(-6)/℃

Specific heat capacity: 0.18Cal/g.℃

Thermal conductivity: 0.0765 Cal/cm.s.℃

Resistance: 1.4x10(-3)Ω·cm

Carbon content: 95%

Sodium and potassium content: <50ppm

2. Application Difference Between T700 And T1000 Carbon Fiber

Many properties of carbon fiber T1000 are better than T700, but considering the actual preparation, cost and other factors, T1000 will have a certain degree of strength loss during untwisting, so it cannot be said that T1000 is better than T700 in any application. It can only be said that theoretically the overall performance of T1000 in any application is better than T700:

T700 is a civilian material, and raw materials can be freely purchased, while T1000 is a material used by military and national defense, and the procurement of raw materials is relatively difficult.

Carbon fiber above T1000 is more suitable for high-end fields such as aerospace, while carbon fiber such as T700 is the highest-grade choice in the civilian field, especially the most ideal material for drone racks. Adapting measures to local conditions and selecting appropriate materials to produce corresponding products is the correct way to open carbon fiber.

3. Cost Difference Between T700 & T1000 Carbon Fiber

In addition to the differences in application fields, the most important difference in the use of Carbon Fiber materials on drones is cost considerations, because drones are also consumer products, no matter which material is selected, the probability of being damaged or scrapped by force majeure factors is very high. The price of T1000 carbon fiber is about 3-5 times that of T700 carbon fiber. We do not recommend using T1000 on drones to increase the cost of such popular products. And the T700 Carbon Fiber has enough performance to make any drone last so long that its owner gets tired of using it.

Pulished on Oct. 23, 2023

Pulished on Feb. 02, 2023